Titanium dioxide R&D and supply.

Apr 22,2025

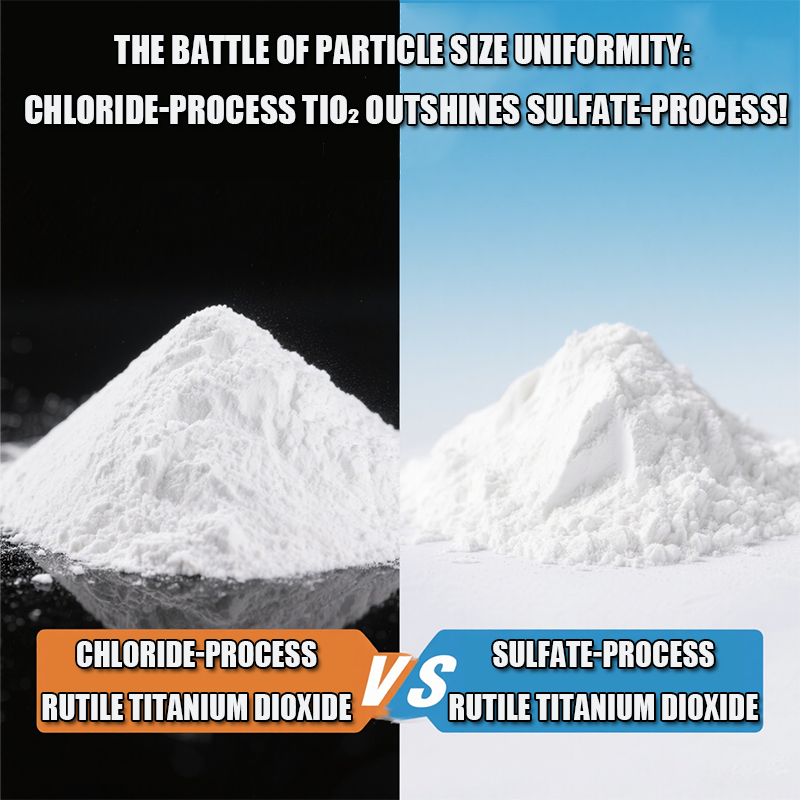

The titanium dioxide (TiO₂) industry has long focused on enhancing product quality, with particle size uniformity being one of the key performance indicators. Recently, a comparative study between the chloride and sulfate production processes has garnered significant attention in the industry. The research findings reveal that chloride-process TiO₂ outperforms sulfate-process TiO₂ in particle size uniformity, marking a breakthrough in chloride-process technology. This discovery not only improves TiO₂ quality but also presents new opportunities for progress across the entire industry.

Traditional Comparison Between Chloride and Sulfate Processes

Titanium dioxide, a vital raw material used in coatings, plastics, paper, cosmetics, and other industries, is produced mainly through two methods: the sulfate process and the chloride process. Due to its lower production cost, the sulfate process has long dominated the market. However, as the demand for higher-quality TiO₂ increases—particularly in terms of particle size uniformity and dispersion—the limitations of the sulfate process have become more apparent.

In contrast, the chloride-process TiO₂ production method offers distinct advantages, allowing for more precise control of particle size distribution and resulting in a more uniform final product. The more uniform particle size enhances the performance of TiO₂ in coatings and other applications. For example, in coatings, uniform particle size results in smoother finishes, better opacity, and improved durability, ultimately enhancing the product's overall performance.

Technical Breakthrough in Particle Size Uniformity

By comparing the particle size uniformity of TiO₂ produced through both processes, researchers have found that chloride-process TiO₂ has a natural advantage in controlling particle size distribution. The high temperature and pure chlorine gas used in the chloride process help minimize impurities, leading to a more uniform and stable crystal structure. Additionally, the precise control of temperature and pressure in the chloride process ensures consistency in particle size distribution across production cycles.

With further optimization of the process, the particle size uniformity of chloride-process TiO₂ has been significantly improved, reducing particle size deviation by nearly 30% compared to traditional sulfate-process TiO₂. This advancement not only enhances the performance of TiO₂ in a wide range of industries but also strengthens its competitiveness in high-end markets.

Industry Impact and Future Outlook

Particle size uniformity is crucial for TiO₂ applications, particularly in industries such as coatings, plastics, and rubber, where uniform particle size significantly improves product performance. For instance, in automotive coatings, uniform particle size enhances adhesion, wear resistance, and overall durability; in plastics, it increases gloss and UV resistance.

As the advantages of chloride-process TiO₂ in particle size uniformity become increasingly apparent, it is expected that more companies will invest in and adopt chloride-process technology. This will not only improve product quality but also drive the global TiO₂ industry towards higher-end, more eco-friendly, and sustainable development. In the future, with continued technological advancements, chloride-process TiO₂ is expected to capture a larger market share, becoming the dominant product in the industry.

In conclusion, the superiority of chloride-process TiO₂ in particle size uniformity marks a significant breakthrough in TiO₂ production technology. This advancement not only enhances product performance but also provides strong support for the industry's green and sustainable development goals.