Titanium dioxide R&D and supply.

Apr 21,2025

A groundbreaking development in the pigment and coating industry is making waves: the innovative application of Chloride-Process Titanium Dioxide (TiO₂) has boosted UV resistance by an astonishing 50%. This technological breakthrough is not only elevating the quality of coatings, plastics, and paper products, but it also offers a new solution for global environmental challenges. The introduction of this technology makes it possible to produce more eco-friendly, durable, and high-performance coatings, poised to revolutionize the future of the coatings industry.

The Revolutionary Path of Chloride-Process TiO₂

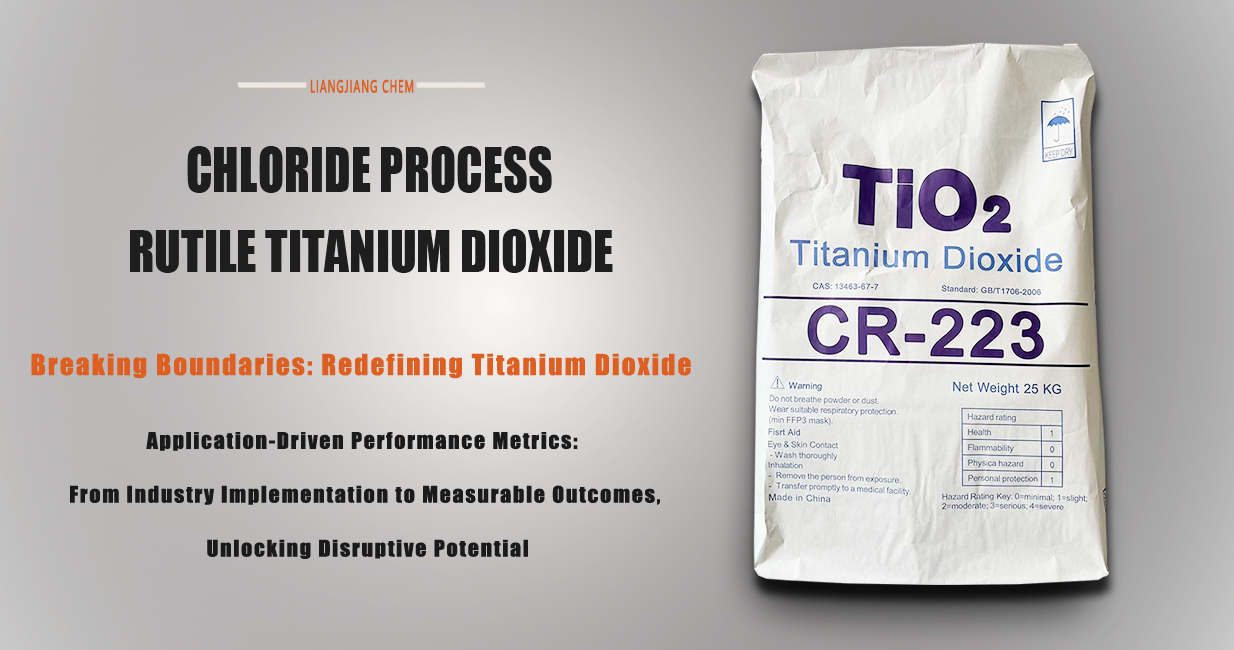

Titanium dioxide (TiO₂), a widely used pigment, has extensive applications across industries such as coatings, plastics, paper, and cosmetics. For decades, TiO₂ production has relied on two main methods: the sulfate process and the chloride process. Among these, the chloride process has become the mainstream due to its efficiency and environmental benefits, though it has faced challenges regarding UV resistance.

However, with the emergence of new technologies, the UV resistance of chloride-processed TiO₂ has reached a breakthrough. Researchers have discovered that by optimizing the chloride process, the crystal structure of TiO₂ can be stabilized, significantly enhancing its UV resistance. This advancement has resulted in a 50% increase in UV tolerance, meaning that coatings and products exposed to sunlight can maintain their color and stability for much longer.

Far-reaching Impact on the Industry

This breakthrough is undoubtedly a "revolutionary" step forward in the coatings industry. With improved UV resistance, the lifespan of coatings and plastic products will be significantly extended. This means that coatings and products exposed to sunlight for extended periods will be better able to resist fading, peeling, and aging. This is especially important in sectors such as construction, automotive, and outdoor infrastructure, where UV resistance is critical.

Moreover, the widespread adoption of this technology will further drive the growth of the environmental sector. Chloride-processed TiO₂ not only offers superior UV resistance but also has a lower environmental impact during production. As a result, more companies are likely to adopt this technology to reduce pollution and carbon emissions during manufacturing.

Looking to the Future

As the demand for eco-friendly, durable, and high-performance products continues to rise, chloride-process TiO₂ is poised to capture a larger share of the market in the coming years. With further refinements in production techniques, this technology will find broader applications in coatings, plastics, textiles, and other industries. Consumers worldwide will soon enjoy more durable, eco-friendly, and aesthetically pleasing products.

In conclusion, the breakthrough in chloride-process TiO₂ technology is not only a symbol of technological progress but also a crucial step in the industry's transformation. With the widespread adoption of this new technology, the future of products will be greener, more durable, and more visually appealing. There’s every reason to believe that the titanium dioxide industry is set for a brighter future on a global scale.