Titanium dioxide R&D and supply.

Jul 31,2025

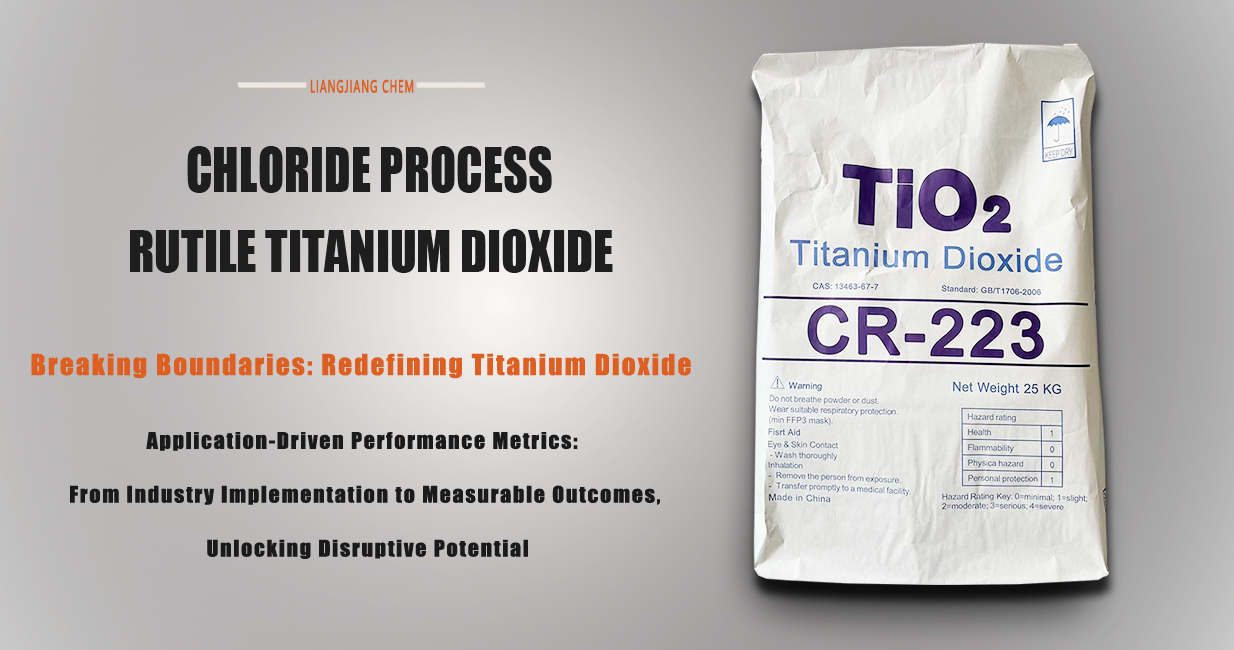

[Industry Insight] As polycarbonate (PC) demands soar in electronics and automotive lenses, traditional titanium dioxide-induced yellowing and embrittlement have become critical pain points. Groundbreaking validation from global labs reveals: Chloride-process rutile titanium dioxide is redefining PC performance limits through advanced surface engineering!

UV Shielding Revolution

Zirconia-alumina dual coating creates a "UV shield," boosting UV absorption to 99.5% (ASTM G155). This prevents PC chain scission, ensuring ΔE<2.0 for automotive lamp covers after 10 years (vs. industry ΔE<5.0).

Zero Catalysis at High Temp

Organic silicone treatment neutralizes photocatalytic activity. At 300°C injection molding, PC light transmittance retains 91% (ordinary sulfate process ≤85%), eliminating medical housing fogging.

Dispersion Breakthrough

0.2μm monodisperse spherical particles (BET 15m²/g) with 18g/100g oil absorption reduce surface area by 40%, cutting screw shear energy and lowering PC masterbatch costs by 12%.

Covestro’s PC lines have fully adopted chloride-process rutile TiO₂ (e.g., CR-223). Verified data shows:

Weathering life 3X longer for electronic housings (QUV 4000h vs. 1200h)

Molding yield jumps to 99.3% (vs. 95.1% with traditional grades)

“This is pivotal for functional PC,” states Covestro’s CTO. “Chloride-process rutile titanium dioxide resolves the conflict between transparency and weatherability, enabling 5G radomes and LiDAR lenses.”

▶ Future Outlook

Per Grand View Research, the global weatherable PC market will hit $22B by 2027. chloride-process rutile TiO₂ will become the standard for premium PC applications, driving sustainable innovation!