The yellowing in Masterbatch through the action of heat is an issue that many producers, such as Liangjiang, strive to prevent. “When you see plastic products turning yellow, many times the quality of that material is probably going down,” he said, “And customers don’t want to see that. The colors of Masterbatch are affected by temperature, feel like old and dirty. We have encountered numerous such cases at Liangjiang when a clear, bright Masterbatch became yellow due to heat post-processing or during use. That yellowing is not just about color; it can indicate that the material is breaking down from within. So, knowing why Masterbatch yellows when exposed to heat, and how factors such as TiO2 chloride come into play, is crucial for producing strong, long-lasting goods. We have experimented with many types of Masterbatch to select the perfect type for this particular application, especially in terms of heat stability, so our clients are assured of quality every step of the way

Why the Masterbatch will turn yellow under high temperature and how to solve it

Yellowing occurs primarily because heat precipitates chemical reactions in a Masterbatch’s constituents. When heated, plastic can conduct with oxygen in the air causing some areas to form a yellow substance on the surface. This process is called oxidation, and it can be hastened if the plastic contains impurities or weak stabilizers. On occasion, the Masterbatch might contain traces of raw materials or additives that are heat intolerant. “If the stabilizers cannot protect the plastic, heat will start breaking down those polymers on the inside, especially if that internal environment should not reach 60 degrees,” she says. This can cause the fabric to lose its original colors, as well as its strength. We keep close eyes on the quality of raw materials at Liangjiang. We have special heat-resistant stabilizers and additives that help to slow down oxidation. And how a Masterbatch is made also makes a difference. In the case where the mixing temperature is too high or the time period are long, it will allow to begin yellowing Masterbatch at a rate before reaching order! We put samples through heating treatments for various times and temperatures to see how stable they might be. Occasionally, we experiment with various stabilizer mixes to see what works best. Antioxidants and UV stabilizers, if used in all the right places and in high enough levels, go a long way. But all stabilizers are not alike; some work best for curbing yellowing at lower temperatures, others with higher ones. Another thing is processing conditions. When the plastic is heated too quickly or receives uneven heat during forming (molding or extrusion) these hot spots with the potential to cause yellowing are created. That’s why Liangjiang tells customers watching their machines closely and maintaining a relatively consistent temperature. Yellowing is also influenced by the humidity and light exposure of a storage environment. Dry and shading groove master batch is beneficial to reduce the early color difference. In my experience, a small switch of the stabilizer type or of the processing speed can cut yellowing in half. It’s not so much adding more chemicals as wisely choosing them and managing the whole process. The Masterbatch yellowing is a complicated phenomena, but can be nicely handled with some diligent work

How Does the TiO2 Chloride Influence the Yellowish of Masterbatch

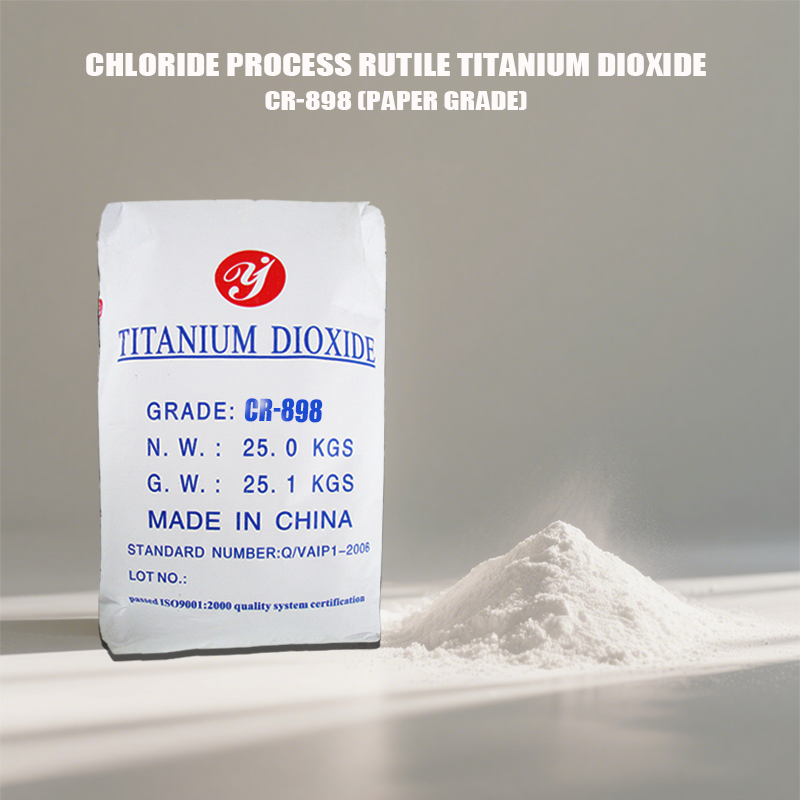

Titanium dioxide, TiO2, is a widely adopted white pigment in Masterbatch for bright and opaque plastic applications. But not all TiO2 is the same. Chlorine and chlorides are sometimes present in chloride process TiO2 at trace levels. These chlorides may be problematic when the Masterbatch is heated. We have found at Liangjiang that TiO2 chloride impurities can accelerate the yellowing under heat. The chloride functions like a catalyst does in a chemical reaction, causing the plastic to break down more quickly. Under the influence of heat, the chlorides can react with either polymer chains or (partially) deactivated stabilisers and inhibiters and discolour/embrittle the material. If, for instance, you use a TiO2 pigment with high chloride content in a Masterbatch for an end product having repeated heating cycles – over which the yellowing will become visible earlier and more intense. This is particularly the case for articles where it has to withstand an outdoor exposure or a warm climate. Our tests indicate that high chloride content makes a big difference in thermal stability. That’s why Liangjiang makes a careful process to choose the TiO2 pigment with ultra low chloride. We also test each batch of material before it is used in production. In some cases, we even add supplemental stabilizers for the sole purpose of capturing (bind-up) any remaining chlorides. This practice significantly enhances the heat-yellowing resistance of the Masterbatch. Yet another consideration is that chloride-induced yellowing can be evasive, as it does not always happen right away. In some cases, the material appears all right at first but then turns yellow with weeks or months of exposure to heat. This extended consequence is problematic because complaints from customers can come well after products have been produced and left the factory. We employ these ideas with our partners to assist them in selecting the appropriate materials and to understand risks involved. TiO2 chlorides also contribute to properties in various machines to which the Masterbatch is submitted. For instance, some lines of extrusion equipment can experience deposits or discoloration in side their apparatus as a result of chloride reaction. This must be well controlled and cleaned, for which we furnish our technical service. In sum, chloride-free or low-chloride TiO2 coupled with proper stabilizers and processing steps is the key to prevent heat-related yellowing. This is the knowledge we have accumulated by working with the customers and improving our products at Liangjiang for years, even to compete the harsh conditions, Our Masterbatch

Masterbatch Yellowing Problems and Solutions for Bulk Buyers

Masterbatch is a kind of, a special plastic additive which would add color or other properties to the final product of plastic. Yellowing is one of the main difficulties a lot of people experience for Masterbatch. Yellowing refers to the fact that the plastic or article of manufacture will become, after a period of time and under the influence of light/dark fac tors and heat, discolored or “yellow”, in appearance. This is possible even if the plastic was originally white or another color. Yellowing is a big problem, because it makes the plastic appear dirty, old or bad, which isn’t so great if you’re trying to sell washing machines and more people now want them to look nice and clean

One of the most common reasons for yellowing Masterbatch is heat. When plastic is manufactured, it undergoes a process called heating or melting, and if the components in Masterbatch aren’t good at tolerating heat, they can start to decompose. This degradation is accompanied by yellow pigmentation. One reason is the type of chemicals in the Masterbatch. Other chemicals, as well as oxygen or sunlight, react with the linen and can cause yellowing. Sometimes, the Masterbatch itself has cheap, low-quality composition that is more likely to yellow

It is quite important to keep away from Yellowing for those wholesalers who purchase and use large quantity of Masterbatch in making factories or products. For this, buyers need to select the Masterbatch that has been tested well and prepared with good quality materials. They should ask their supplier if its Masterbatch has good heat resistance and passed tests that prove it won’t readily yellow. Now if you buy brand like Liangjiang can be assured to a large extent, because the Masterbatch produced by the Liangjiang is yellowing resistance is very strong. Plus, be sure to store the Masterbatch properly as a buyer. If you store it away from too much heat, light or moisture, for example, and keep handling to a minimum, your plastic will stay fresh and not yellow even before the manufacturer makes it. When buyers do the same, they receive higher quality plastic products that last longer and function better, contributing to their business’s success

Why Testing TiO2’s Thermal Stability Is Essential to Quality Masterbatch

Titanium dioxide, or TiO2 for short, is a very important material in Masterbatch to brighten plastics white and colorful. TiO2 ensures that the colors are bold and the plastic looks good. But TiO2 can be problematic at times if it is not thermally stable. Hence studying thermal stability of TiO2 becomes paramount. 1.4. Thermal stability is a measure of how well the TiO2 can withstand high temperatures without any changes or decomposition occurring

However, when manufacturing plastic Masterbatch with TiO2, because of the extremely high temperature, pet heat can be used a lot. If the TiO2 is thermally non-stable, its decomposition can be initiated during this heating. When that occurs, it may result in plastic yellowing or reduced color intensity. This is why testing under thermal about TiO2 content is so important to make sure whether the Masterbatch will hold color and quality. Testing helps determine whether the TiO2 is able to remain robust and safe even after being heated many times

Here at Liangjiang, we ensure that we test our TiO2 to verify its thermal resistance before adding it to the Masterbatch. We test it in various temperatures and conditions to determine how well it works. This has enabled us to develop a Masterbatch which doesn’t change color quickly and remains the same for longer. Testing for thermal stability also helps us avoid issues that might occur down the line in the production process, which saves time and money for our buyers. Without such testing, Masterbatch might seem just fine at first ride but yellow later on when under heat, a big headache for makers of plastic

In other words, thermal stability testing is a sort of safety check that will ensure your Masterbatch processes well on heat passes and keeps plastic looking bright and fresh. Any wholesale buyers of the best Masterbatch will always ask whether the product’s TiO2 has been submitted to some thermal stability testing. Selecting Liangjiang Masterbatch enables buyers to receive TiO2 made from the above important tests, achieve high quality and less yellowing

Where to purchase Masterbatch at a discount and highly anti-yellowing properties

For manufacturers that produce plastic products, sourcing the right place to buy Masterbatch in bulk amounts is crucial. Buying wholesale Masterbatch, you would be wise to search for suppliers who provide a high-quality Masterbatch that is highly resistant to yellowing. Anti-yellowing: This indicates that the Masterbatch is produced to prevent plastic from yellowing after heating or exposure to light. Procuring a Masterbatch with such properties helps ensure that plastic products remain fresh and clean for an extended period

Liangjiang would like to recommend high-quality anti-yellowing Masterbatch for wholesale purchasers. We are recognized for producing Masterbatch that is not easily yellowed because we employ first-class materials and we inspect each batch rigorously. We use tested for heat-stability TiO2, to make Masterbatch glow bright- whitening product. Liangjiang also employs special additives that serve to protect the plastic from heat and sunlight, both of which tend to be problematic factors involved in yellowing

There are many advantages for the wholesale buyers who cooperate with Liangjiang. For one thing, they receive Masterbatch that has a longer shelf life and stays color stable, which allows their products to look more appealing on the store shelves. Second, Liangjiang has a favorable price for big orders – you can buy high-quality Masterbatch at an inexpensive cost. Our company will provide strong technical support and technology advice to buyers, assist them in selecting Masterbatch. That means: buyers don’t have to concern themselves with yellowing issues or product failure

If you want to purchase Liangjiang, please contact sale team or you can visit our website for detailed information. We provide samples and detailed data on our Masterbatch so that potential buyers can test it out first and find out how well it does for them. If you choose Liangjiang, you’re choosing a partner who is devoting about Masterbatch quality and business that will help customers to be more successful in today’s quality driven marketplace. So we will push our quality to your demands. Liangjiang is the wise choice in your selection of Masterbatch for yellowing issue

Table of Contents

- Why the Masterbatch will turn yellow under high temperature and how to solve it

- How Does the TiO2 Chloride Influence the Yellowish of Masterbatch

- Masterbatch Yellowing Problems and Solutions for Bulk Buyers

- Why Testing TiO2’s Thermal Stability Is Essential to Quality Masterbatch

- Where to purchase Masterbatch at a discount and highly anti-yellowing properties